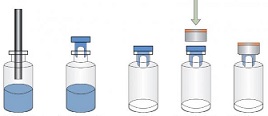

灌装产线曲线打印和pdf报表软件已完成性能测试,正式上线销售。

软件可打印的曲线包括如隧道烘箱温度,压差,cipsip相关过程参数等。

架构:局域网中连网线运行即可,无需变更原有系统

功能:按时间检索触摸屏曲线数据(原始数据),

获取数据后绘制曲线,生成pdf报告可进行归档,

连接打印机后可以打印成纸张签名归档。

优点:

可弥补原有系统曲线无法打印的不足。

可按时间和曲线名检索历史曲线和数据。

无需变更原有系统,安全可靠。

弥补有纸记录仪卡纸或色带不好的情况造成的记录缺失。

可自定义报表格式(显示检索时间,传感器编号)

投入小,无需配套scada.

从原始数据中获取曲线数据,不存在二次加工问题[附软件数据处理声明]

系统选项功能:用户管理,审计追踪

遵循GMP5设计流程,提供验证服务

*可定制升级,根据批记录自动生成对应曲线

*可定制升级,打印采样时刻的所有传感器测量值

详询销售工程师。

----------English----------

Bosch filling line curve printing and pdf report software has completed performance testing and officially launched for sale.

Software printable curves include, for example, tunnel temperature, pressure differential, and cip-si p related process parameters.

Architecture: The network cable in the local area network can be operated without changing the original system

Function: Retrieve touch screen curve data (raw data) by time,

After acquiring the data, draw a curve and generate a pdf report for archiving.

When connected to a printer, it can be printed as a paper signature file.

Advantage:

The system can make up for the lack of printing of the original system curve.

You can retrieve historical curves and data by time and curve name.

No need to change the original system, safe and reliable.

Make up for missing records due to paper recorder jams or bad ribbon.

Customizable report format (display search time, sensor number)

Small investment, no need for supporting scada.

Obtain curve data from the original data, there is no secondary processing problem [with software data processing statement]

System option functions: user management, audit trail

Follow the GMP5 design process and provide verification services

-Can be customized to upgrade, and automatically generate corresponding curves based on batch records

-Customizable upgrade, print all sensor measurement values at the sampling time

Pls consult our sales engineer for details.

推荐阅读: